Data May Be The Way Forward For Crane Safety

Lifting with heavy equipment in confined worksites can often mean that unexpected hazards come about. Pick and carry cranes are most susceptible to these types of undetected dangers when operating on loose or uneven ground. This can have catastrophic impacts when under load and can have dire consequences.

Lifting with heavy equipment in confined worksites can often mean that unexpected hazards come about. Pick and carry cranes are most susceptible to these types of undetected dangers when operating on loose or uneven ground. This can have catastrophic impacts when under load and can have dire consequences.

In an effort to reduce these risks, crane safety company Robway Safety developed its Dynamic Load Moment Indicator (LMI) system, which monitors the attitude of the crane and adjusts the capacity it can safely carry in real time.

Jon Koval, Robway Safety General Manager, said before this type of technology was introduced, operators were required to use paper charts and load duration tables when operating a pick and carry crane.

“These weren’t just unproductive, they also took the operator’s mind of the task at hand when they need it the most,” he said.

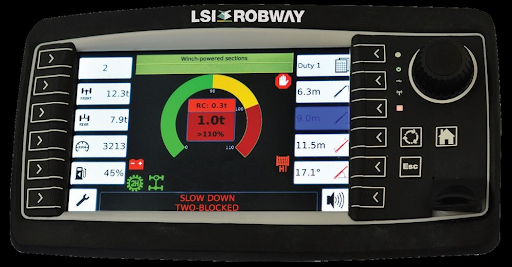

“With the LMI system, an operator is now able to actively monitor the load while it is in transport, while the system recalculates the maximum capacity, lifting parameters and angle and length of the boom.

“It allows the operator to see what percentage of their safe lifting capacity is at any given instant, similar to how a speed alert works within a car,” Koval said.

The system was designed through a joint development between Terex and TRT. Robway developed the mathematical models for calculating the loads and boom length, while the other companies assisted in developing the algorithm to calculate the rated capacities based on the slope, boom angles and length.

This was then placed into the control system to monitor the load and provide warnings through the dashboard of the crane. If a crane reaches its maximum operating capacity, it will be unable to enter any unsafe configurations but still able to retreat back to a safer position

In addition to this system, Robway has also developed a datalogging system that works similar to a plane’s black box. Originally based on European standards, the technology records every action taken within the crane to monitor operator behaviour and assist investigations.

Koval said the system had immediate results when installed on one of their client’s machines.

“The data can be used to figure out the cause of any faults in an investigation, creating a level of accountability for the operator. However, it can also show if an incident occurs that wasn’t their fault. It does this by recording the movements of the crane in real time, so that any time a safety feature is overridden, or the crane is brought outside its safe working envelope, an alert can be sent out,” he said.

“We found that operator behaviours changed rapidly once it was possible to record what was being done with the crane.”

Robway’s next key focus is data analysis, as the system can record millions of individual numbers that need to be properly interpreted in order to provide meaningful insight.

This data can be used for more than just safety. Robway has been able to combine it with internet reporting to assess value of cranes, helping companies decide when to sell the crane.

“We found our customers were able to use the data to find out how to get the most value from their assets. They were able to evaluate when the crane had reached the halfway point in its lifespan and could make informed sales decisions,” Koval says.

Remote system accessibility is also an area of development that Robway is researching, particularly with advances in cellular network technology.

The company aims to provide a system which will allow live video feed of a lift, which it believes will improve operator behaviour and collaboration, as offsite assistance can help provide assistance for particularly difficult lifts.

Koval said enhanced accessibility is key for the future of the company’s offering, especially as the consumer market drives expectations within the cranes industry.

“Smartphone technology has made accessing data and information even more readily available than ever before. Users are able to pick up their phone and get what they want in seconds,” he explained.

“We’re also looking to build off the multi-billion-dollar research and development happening for consumers and adapt it for the future of crane safety.” If you would like to read the full article head on over to the Cranes and Lifting website.